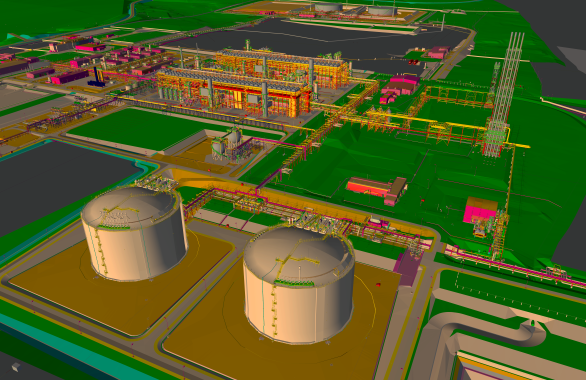

Prigorodnoye production complex

The Prigorodnoye Production Complex comprises a liquefied natural gas (LNG) plant and an oil export terminal (OET)

The complex covers up to 236 ha.

Projects implemented for Prigorodnoye production complex

Installation of coolers in SS410/420 transformer substations

SS-410 and SS-420 comprise of 10-off transformer rooms in each building. High temperature has been observed in summer season and caused overheating of transformers. To mitigate the risk of equipment tripping, some temporary measures have been taken, such as transformer rooms’ door opening and installation of fans for summer season.

The four options previously studied by Sakhalin Energy LLC have been reduced to one, to install Air Conditioning Units (ACU).

Currently, the project is at the Detailed Design stage.

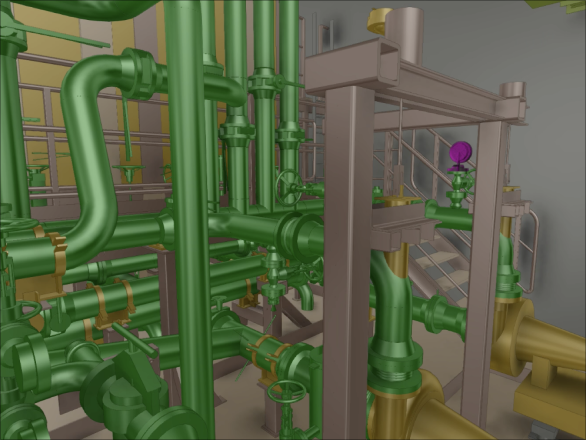

LNG К1440 1st stage anti-surge valve

High vibration levels around 14UCV842 are known issue and were investigated in past after delayed train start-up due to loosened instrument fittings on 14UCV-842. Root cause for that failure was valve vibration. Further investigation revealed that induced vibration is the bad factor in this vibration issue.

Currently, the project is at the Detailed Design stage.

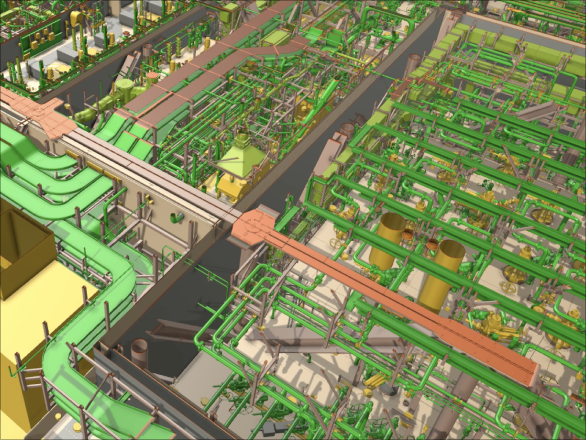

Natural gas pressure increase

Currently, the natural gas working pressure downstream the pressure reduction station is up to 59.9 barg, which includes 10% margin of safety from the relief valve actuation pressure 66.5 barg. Liquefying efficiency to improve as the pressure increases and consequently, at the same cooling agent capacity, the flowrate to increase, when the working pressure rises. The point is to maximize the allowable working pressure and stay within the safe range from the set point of the relief valve.

Currently, the project is at the Detailed Design stage.